Beijing-Zhangjiakou Intercity Railway New Badaling Tunnel and Great WallRailway Station Projects

2.Shandong university

3.China Railway Engineering Design and Consulting Group Co.Ltd

China is building a 174-kilometer-long Beijing-Zhangjiakou Intercity high-speed Railway, which connects the three venue clusters of Beijing, Yanqing and Zhangjiakou, and traverses through the heart of the Great Wall, a UNESCO World Heritage Site.

China Railway No. 5 Engineering Group Co., Ltd. built the new Badaling Tunnel and Badaling Great Wall Railway Station, which are the most critical, challenging and decisive projects on the line.

The 12.01-kilometer-longNew Badaling Tunnel, parallels the Shuiguan Great Wall, cuts just 4 meters beneath the Qinglongqiao Station on the old Beijing-Zhangjiakou Railway and dives under the Badaling Great Wall twice. The tunnel houses two lines, with a maximum section width of 32.73m at the tunnel-station transition,and an excavation area of 508 m2.

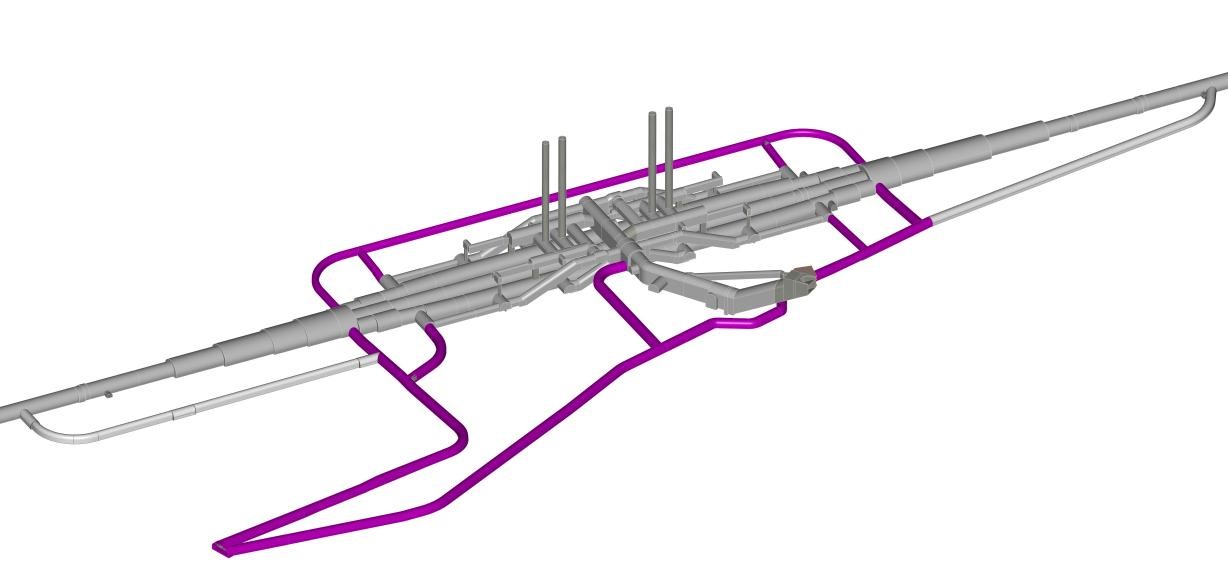

The Badaling Great Wall Railway station has an underground construction area of 39,852 square meters, with a length of 470 meters, maximum depth of 102 meters,passenger exitsand entrances 62 meters above the underground level.The underground station has "three tunnels and three floors". The "three tunnels" refer to three closely spaced parallel tunnels on the platform floor. The first 36 meters at both ends of the station will be three-arched structures, and the 398 in the middle separated tunnels. The "three floors" refer to the platform, entrance, and exit and mechanical floors.

There will be diagonal channels connecting the platform, entrance and exit floors, as well as the underground and ground portions. The entrance and exit channels are on overlaid layers above the middle of the platform floor to separateoutbound and inbound passengers and balance entrance and exitdistribution.

Mechanical caverns are mainly on the exit floor, with a minimum horizontal spacing of 2.4 meters and a minimum vertical spacing of 4.5 meters. The station has 78 cavernsincluding the main cavern, 88 section forms and multiple intersections. Annular rescue channels allow for prompt rescue and complete coverage in the event of emergencies.

The Station uses the close-cut method, with eight subchannels set for construction at the No. 2 inclined shaft. The cavern construction is organized by the principles of "paralleled and staggered arrangement" and "lower layers and marginal sections first" to ensure safety. For vertical air shafts, a raise borer drills a pilot hole from the surface down, then a drill boresfrom bottom up for the first expansion, followed by the drill and blast method to expand the shaft again from the surface down.The inclined entrance and exit passagesarecompleted with the "4 layers and 8 sections" method, surface-down excavation in four layers and the bottom-up lining in three runs.

During the construction of the Station and the large-span station-tunnel transition , new technologiesincludingpre-stressed anchor cable support, DFHZexcavation, super and variable section tunnel second lining, long-life concrete construction, three separate closely-spaced tunnels, three-arch tunnel construction, ventilation for complex underground caverns, are used to solve the various technological challenges encountered.

Since construction started, a multi-channel, smart cloudcomputing management system, which includesBIM, tunnel face geology digital image processing, real-time test monitoring and measurement information collection, as well as traffic guidancebased on man-machine positioning, has helped achieve multi-channel, safe and fast operation.

The project has applied the electronic detonator accurate and micro-damage blasting technology for the first time. During construction of the tunnel under the Great Wall and of the closely spaced caverns, the vibration velocity of explosions is controlled within 0.1cm/s and 4cm/s, respectively. This not only protects the Great Wall, but also ensures safe construction and surrounding stability. Deformation of the surrounding rocks is controlled within 2cm. No surface subsidence has occurred.

We developed the tunnel secondary lining concrete quality management system, from which we can timely monitor the mixing station, the laboratory inspection data and other quality and safety data as well. We adopted 300-year durability secondary lining concrete, spray curing trolley, moisture preservation and heat preservation curing film,as well as other new materials, new processes and new machineries, to strengthen the process quality control, which assures the project quality, and achieves "Excellent Construction & Intelligent Beijing-Zhangjiakou Railway".

With reasonable planning and construction organization of the eight subchannels, construction of the 2941-meter-long Badaling Station, took just 372 days, averaging7.9 meters per day.

By implementing proper construction approaches, the Badaling Great Wall Railway Station's initial lining was completed with stable structure and quality lining, achieving the construction goal of safety, quality and intelligence.

中国岩石力学与工程学会微信订阅号

中国岩石力学与工程学会微信订阅号

科普岩石力学与工程

科普岩石力学与工程