National Major Project - Jiangeyuan Expressway Tabaiyi Tunnel Construction

发布时间:2022年09月27日

浏览数:3425

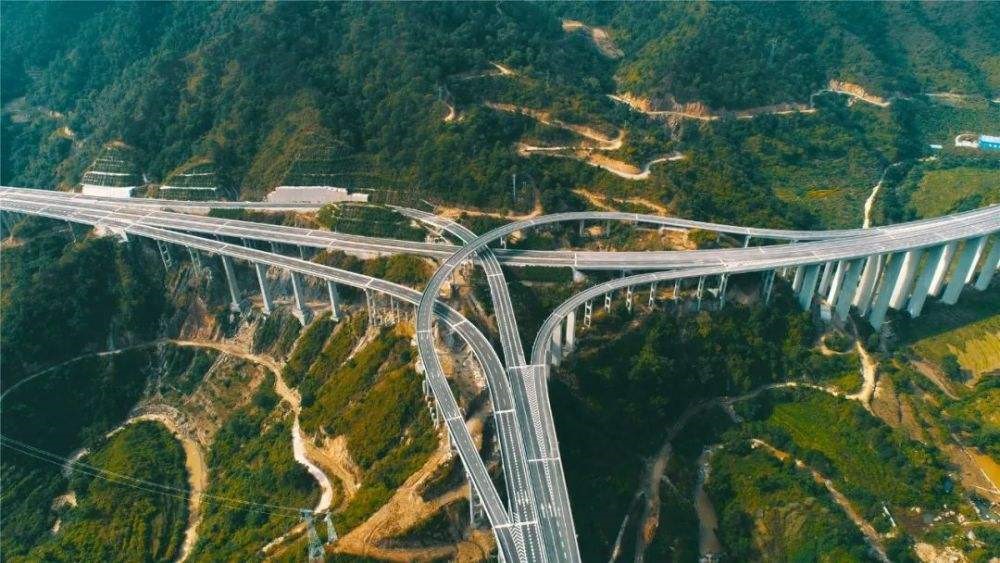

Jiangeyuan Expressway is an expressway located in Yunnan province, it connects Jianshui County, Yuanyang County and Gejiu City in Honghe Prefecture, Yunnan Province, with a total length of 124.53km and a bridge-tunnel ratio of up to 72%, designed as a two-way four-lane expressway. It is one of the most difficult highway projects under construction in Yunnan province, and the key project for the "five-network" construction in Honghe Prefecture, Yunnan Province and the five-year comprehensive transportation construction plan. As a strategic transportation link for Honghe Prefecture to integrate into the regional development, it will become an important transportation hub open to ASEAN.

The Tabaiyi Tunnel is a control project for the construction of the Jiangeyuan Expressway. It is located on the southern part of the Yunnan-Guizhou Plateau and at the eastern foot of the Qinghai-Tibet Plateau. The total length of this tunnel is 2613m, with a maximum burial depth of 297m. The whole construction site is within the structural erosion zone, and dominated by strongly weathered and moderately weathered slabs, and the proportion of V-type surrounding rock is as high as 95.5%. The width of the tunnel excavation section is 16m, the maximum thickness of the middle rock wall is 21.4m, and the minimum thickness is 14m, which belongs to the small-distance tunnel. Although thedepth of the Tabaiyi Tunnel is less than 300m, due to the influence of regional faults, the Tunnel passes through several faults and weak zones, with strong tectonic movement, joint fissure water development, fractured structure. It is well known as a "stuck neck" project, and has become a typical example of large deformation of surrounding rock in small-distance tunnels under the influence of fractured and broken weak zones in China.

Since the starting date of the project (April 2018), the Tabaiyi Tunnel has frequently experienced engineering geological diseases such as mud and water inrush, large deformation of the fault fracture zone, landslides, slumps, inverted arch uplifts, initial support encroachment, and secondary lining cracking. Among them, the maximum mud and water inflow in the Tunnel is 4500m3, and the secondary lining trolley weighing 70t is moved by 25m; the maximum deformation of the surrounding rock in the fault fracture zone is over 3100mm; the cumulative arch exchange length of the double tunnel is 1836m, and the arch exchange rate is as high as 37%, the annual drilling depth is less than 70m, which seriously restricts construction safety, prolongs construction period and increases investment. In July 2021, the Tabaiyi Tunnel introduced the compensation mechanics theory and high-stress NPR anchor cable compensation technology proposed by Academician Manchao He, and carried out the research on the "excavation compensation method for large deformation disasters in small-distance tunnels which pass through multi-level fault fracture zones, and key technology of dual gradient grouting" and on-site demonstration engineering practice.

After nearly a year of joint research (2021.7-2022.7) by the team of China University of Mining & Technology, Beijing led by Academician Manchao He, and the technical team of China Power Construction Honghezhou Jiangeyuan Expressway Co., Ltd., the large deformation disaster of the Tabaiyi Tunnel was effectively controlled by using new theories, new technologies, new materials and new methods. Its meter-level asymmetric deformation was effectively controlled within 300mm, which solved the technology issues that the NPR anchor cable could not be anchored and local high-pressure water inflow due to the water-rich, mud-bursting, and broken surrounding rock, and achieved the major technical breakthrough of "zero" arch change, "zero" intrusion and "zero" water inrush of the initial support of the small-distance tunnels which pass through the multi-level fault fracture zone.

In conclusion, the Tabaiyi Tunnel has achieved remarkable results in the control of large deformation disasters in small-distance tunnels which pass through multi-level fault fracture zones, laying a foundation for theoretical innovation and engineering practice for solving world-class tunnel engineering problems. The problem-solving methods for the "stuck neck" project - the Hebaiyi Tunnel will lay a foundation for the completion of the Jiangeyuan Expressway construction, further revive the "three thousand and four hundred years" history and culture of Honghe Prefecture, and accelerate regional economic development and rural revitalization.

The Tabaiyi Tunnel is a control project for the construction of the Jiangeyuan Expressway. It is located on the southern part of the Yunnan-Guizhou Plateau and at the eastern foot of the Qinghai-Tibet Plateau. The total length of this tunnel is 2613m, with a maximum burial depth of 297m. The whole construction site is within the structural erosion zone, and dominated by strongly weathered and moderately weathered slabs, and the proportion of V-type surrounding rock is as high as 95.5%. The width of the tunnel excavation section is 16m, the maximum thickness of the middle rock wall is 21.4m, and the minimum thickness is 14m, which belongs to the small-distance tunnel. Although thedepth of the Tabaiyi Tunnel is less than 300m, due to the influence of regional faults, the Tunnel passes through several faults and weak zones, with strong tectonic movement, joint fissure water development, fractured structure. It is well known as a "stuck neck" project, and has become a typical example of large deformation of surrounding rock in small-distance tunnels under the influence of fractured and broken weak zones in China.

Since the starting date of the project (April 2018), the Tabaiyi Tunnel has frequently experienced engineering geological diseases such as mud and water inrush, large deformation of the fault fracture zone, landslides, slumps, inverted arch uplifts, initial support encroachment, and secondary lining cracking. Among them, the maximum mud and water inflow in the Tunnel is 4500m3, and the secondary lining trolley weighing 70t is moved by 25m; the maximum deformation of the surrounding rock in the fault fracture zone is over 3100mm; the cumulative arch exchange length of the double tunnel is 1836m, and the arch exchange rate is as high as 37%, the annual drilling depth is less than 70m, which seriously restricts construction safety, prolongs construction period and increases investment. In July 2021, the Tabaiyi Tunnel introduced the compensation mechanics theory and high-stress NPR anchor cable compensation technology proposed by Academician Manchao He, and carried out the research on the "excavation compensation method for large deformation disasters in small-distance tunnels which pass through multi-level fault fracture zones, and key technology of dual gradient grouting" and on-site demonstration engineering practice.

After nearly a year of joint research (2021.7-2022.7) by the team of China University of Mining & Technology, Beijing led by Academician Manchao He, and the technical team of China Power Construction Honghezhou Jiangeyuan Expressway Co., Ltd., the large deformation disaster of the Tabaiyi Tunnel was effectively controlled by using new theories, new technologies, new materials and new methods. Its meter-level asymmetric deformation was effectively controlled within 300mm, which solved the technology issues that the NPR anchor cable could not be anchored and local high-pressure water inflow due to the water-rich, mud-bursting, and broken surrounding rock, and achieved the major technical breakthrough of "zero" arch change, "zero" intrusion and "zero" water inrush of the initial support of the small-distance tunnels which pass through the multi-level fault fracture zone.

In conclusion, the Tabaiyi Tunnel has achieved remarkable results in the control of large deformation disasters in small-distance tunnels which pass through multi-level fault fracture zones, laying a foundation for theoretical innovation and engineering practice for solving world-class tunnel engineering problems. The problem-solving methods for the "stuck neck" project - the Hebaiyi Tunnel will lay a foundation for the completion of the Jiangeyuan Expressway construction, further revive the "three thousand and four hundred years" history and culture of Honghe Prefecture, and accelerate regional economic development and rural revitalization.

中国岩石力学与工程学会微信订阅号

中国岩石力学与工程学会微信订阅号

科普岩石力学与工程

科普岩石力学与工程